Quality Policy

All AIP employees and associates are committed to exceeding customer expectations for product quality, on-time delivery and best-in-class customer service with a company-wide focus on continuous improvement.

All AIP employees and associates are committed to exceeding customer expectations for product quality, on-time delivery and best-in-class customer service with a company-wide focus on continuous improvement.

Quality Management System

QMS Scope: Product design support, process design and manufacture of blow molded custom applications for multiple industries, including: recreational equipment, lawn & garden, agricultural and water craft industries.

Certified to: ISO 9001:2015 without Design

Certified by: Smithers Quality Assessments

View Our Certificate

Quality is at the core of every part we manufacture, and every Agri-Industrial Plastics employee understands the deep commitment we have to quality at each step.

From design to your assembly line, we constantly analyze and improve production processes to create the best possible product for you and your end customers.

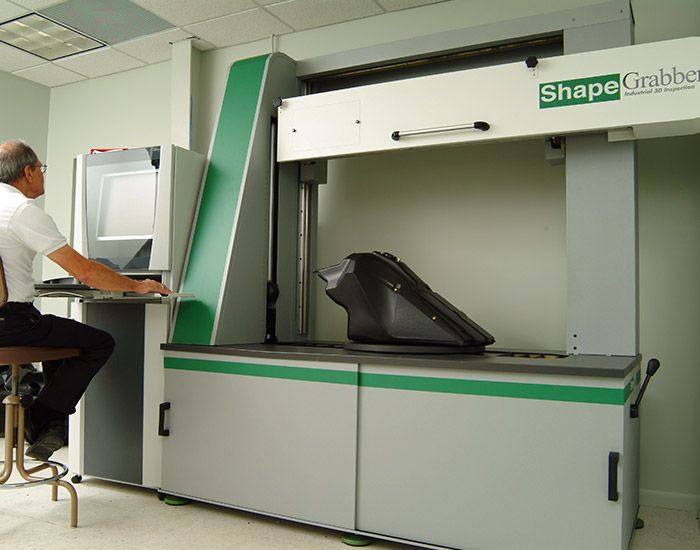

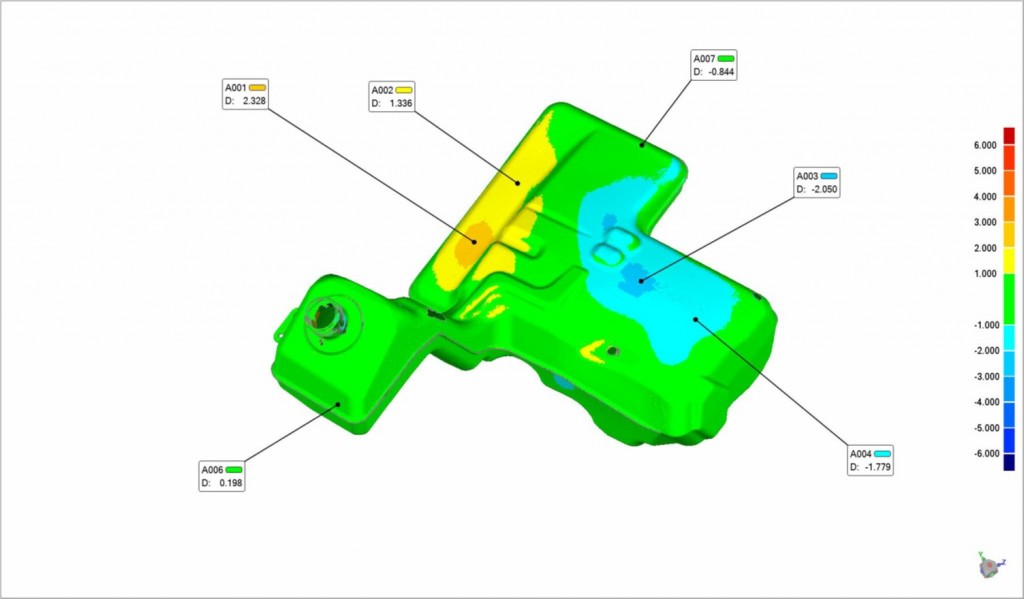

Our laser scanner is used to create a 3D data point cloud of a molded part, that can be compared to the original CAD model. This comparison helps determine how effectively the blow molding process is able to replicate the original design intent. This tool has proven invaluable during the development phase to establish dimensional tolerances and process capability.

Shape Grabber Laser Scanner

Scan Report Example